Top 10 Alloy Powder Graders You Need to Know?

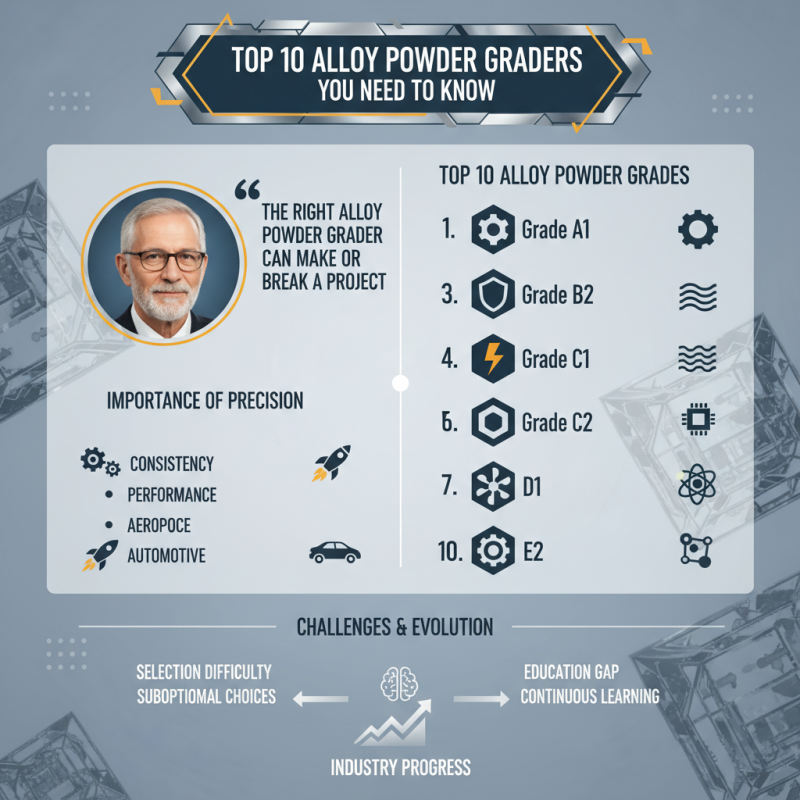

In the world of metallurgy, understanding the nuances of alloy powders is crucial. Experts like Dr. James Hargrove, a leading figure in powder metallurgy, emphasize the importance of precision. He once stated, “The right Alloy Powder Grader can make or break a project.” This insight speaks volumes about the role of quality in this field.

Alloy Powder Graders are vital for ensuring consistency and performance. The industry relies on these grades to cater to diverse applications, from aerospace to automotive. Each grade has specific properties that can significantly impact material strength and durability.

Despite advancements, the selection of an Alloy Powder Grader can be challenging. Many companies still struggle to identify the optimal grades for their needs. Education and awareness are not always up to par, leading to suboptimal choices. As the industry evolves, continuous learning is essential for every professional involved.

Overview of Alloy Powder Graders and Their Importance

Alloy powder graders play a vital role in various industries. They ensure the right material properties for different applications, particularly in additive manufacturing. A report from a leading materials science journal shows that the global demand for alloy powders is projected to grow by 10% annually. This increase underlines the importance of precision in grading.

Different grades of alloy powders possess unique characteristics that influence performance. For example, composition can affect melting points, sintering behavior, and mechanical properties. A study indicates that even a minor variation in particle size can lead to significant changes in strength. Such inconsistencies remind us of the delicate balance engineers must maintain.

Furthermore, the grading process itself can have flaws. Inconsistent testing methods often lead to ambiguous results, which could compromise the final product quality. This gap in standardization highlights a critical area for improvement. As industries rely more on advanced alloys, refining grading techniques is essential for ensuring safety and efficacy.

Key Properties That Define High-Quality Alloy Powders

When looking for high-quality alloy powders, several key properties stand out. First, particle size plays a significant role. Smaller particles often lead to better flowability and packing density. This is critical in applications like 3D printing and powder metallurgy. However, too small a particle size may cause issues like increased agglomeration.

Composition is another vital aspect. The alloy's elemental makeup influences its strength, corrosion resistance, and thermal stability. Some might overlook the importance of uniform distribution of these elements. Inconsistent composition can lead to weak points within the final product.

Additionally, morphology and shape cannot be ignored. Spherical powders tend to flow better than irregular shapes. Yet, different applications may require various shapes. Balancing these characteristics is challenging but essential for optimal performance. By focusing on these properties, manufacturers can ensure they produce high-quality alloy powders.

Criteria for Evaluating and Selecting Alloy Powder Graders

When selecting alloy powder graders, several criteria come into play. The purity of the alloy powder is paramount. Impurities can compromise the final application. Users need to check the chemical composition carefully. Even small percentages of contaminants can alter properties.

Particle size distribution is another crucial factor. It affects the flow characteristics and sintering behavior of the powder. Ideally, a well-graded powder will have a narrow distribution. However, achieving uniformity can be challenging. Sometimes, manufacturers focus on one attribute and overlook others, leading to suboptimal performance.

Additionally, the agility of the grading process must be considered. Quick turnarounds can be tempting, but they may sacrifice quality. It is vital to assess the consistency over time. The grading process should be transparent. Users might find it helpful to seek feedback from previous customers. Not every grading process yields expected results. This aspect requires reflection and careful evaluation.

Top 10 Alloy Powder Graders: Features and Applications

Alloy powders are vital in various industries. They offer unique properties that enhance performance in applications like additive manufacturing and powder metallurgy. The characteristics of each grade can significantly influence the final product. For instance, the fineness of the powders affects how they flow and compact. This directly impacts density and strength in the final parts.

One common application is in aerospace. The right alloy powder can improve weight reduction and thermal efficiency in components. Another area is electronics. Specific alloy powders are tailored for conductivity and hardness. However, choosing the correct grade requires careful consideration of the end-use. Not all powders behave the same under various processing conditions. Some may underperform, leading to unexpected failures. This is an area that requires further thought and attention. Determining the right match isn't always straightforward.

The versatility of alloy powders is both a blessing and a challenge. Many grades exist, and each comes with distinct advantages and drawbacks. It is essential to study and test these materials thoroughly. Understanding the nuances can save time and resources in the long run. Experimentation is often necessary to find the best fit for a particular application. This iterative process can lead to improved outcomes but may also feel overwhelming at times.

Top 10 Alloy Powder Graders You Need to Know?

| Grader | Composition | Application | Particle Size (µm) | Key Features |

|---|---|---|---|---|

| Grade 1 | Aluminium-Zinc | Aerospace Components | 20-50 | High strength, corrosion resistant |

| Grade 2 | Nickel-Copper | Marine Applications | 15-40 | Excellent toughness, weldable |

| Grade 3 | Titanium-Aluminium | Automotive Parts | 10-30 | Lightweight, high-temperature resistance |

| Grade 4 | Iron-Boron | Industrial Equipment | 5-25 | Magnetic properties, wear resistant |

| Grade 5 | Manganese-Aluminium | Construction | 10-20 | Durable, high strength-to-weight ratio |

| Grade 6 | Vanadium-Titanium | Aerospace | 15-35 | High strength, excellent heat resistance |

| Grade 7 | Aluminium-Magnesium | Transportation | 12-28 | Corrosion resistance, lightweight |

| Grade 8 | Chromium-Nickel | Chemical Processing | 10-25 | High corrosion resistance |

| Grade 9 | Cobalt-Chromium | Medical Devices | 10-21 | Biocompatible, wear resistant |

| Grade 10 | Aluminium-Silicon | Electronics | 5-15 | Excellent conductivity, lightweight |

Future Trends and Innovations in Alloy Powder Grading Technology

The landscape of alloy powder grading is evolving rapidly. Innovative technologies are reshaping how we assess and categorize alloy powders. Machine learning is making significant strides in this domain. It helps in identifying patterns in grading data. This leads to more accurate results. However, reliance on technology raises questions. Are we overlooking human expertise in the process?

3D printing continues to influence alloy powder grading as well. It requires precise particle size distribution for optimal results. Improved grading techniques enhance the quality of the final product. Yet, this reliance on new trends might blur the line between traditional methods and modern innovation. Some gradation techniques may not adapt well to newer materials, exposing gaps in the grading process.

As the industry advances, users need to remain cautious. Emerging trends must be analyzed critically. How do these new methods stand up against established practices? Organizations should not rush into adopting new technologies without understanding their implications. The future of alloy powder grading looks promising, but there are still areas that need careful consideration.