What is a Steering Cylinder and How Does It Work?

In the world of hydraulics, the role of the Steering Cylinder is crucial. According to Dr. Emily Ross, a leading expert in hydraulic systems, “A Steering Cylinder is the heart of vehicle maneuverability.” This device converts hydraulic pressure into mechanical force, allowing vehicles to steer smoothly and accurately.

Steering Cylinders are not just metal tubes; they are sophisticated components that ensure safety. An efficient Steering Cylinder contributes to better handling, while a malfunctioning one can cause serious issues. The complexity of steering systems often leads to oversight. Many individuals underestimate the importance of regular maintenance.

The function of the Steering Cylinder is often taken for granted. It works diligently behind the scenes, making precise movements possible. However, if it fails, the consequences are dire. Understanding its importance can prevent accidents. Each part plays a role in maintaining control and stability, reminding us that every detail matters in vehicle safety.

Definition of a Steering Cylinder and Its Function in Vehicles

A steering cylinder is a vital component in a vehicle's steering system. It is responsible for converting hydraulic pressure into mechanical motion. This mechanism allows drivers to steer the vehicle effectively. Hydraulic fluid flows into the cylinder, pushing a piston. As the piston moves, it turns the wheels. This action provides smooth and responsive handling.

In many modern vehicles, steering cylinders enhance maneuverability. They help drivers navigate tight turns and parking situations with ease. However, steering cylinders can fail or leak. This can lead to decreased steering performance. Drivers might notice difficulty in turning or a loose steering wheel. Regular maintenance can help mitigate such issues.

Understanding how a steering cylinder works is crucial for vehicle safety. Without it, precise steering would be challenging. Drivers should remain aware of any changes in steering feel. Issues may arise quietly over time, often unnoticed until they become serious. It’s essential to be proactive in vehicle care.

Steering Cylinder Performance Data

Components of a Steering Cylinder and Their Roles

A steering cylinder plays a crucial role in vehicle handling. It is responsible for converting rotational motion into linear motion. This process allows drivers to control the direction of their vehicle with precision. Understanding its components can enhance operational efficiency.

The primary components of a steering cylinder include the piston, cylinder body, and seals. The piston creates pressure by moving within the cylinder. As hydraulic fluid fills the cylinder, it pushes the piston, facilitating steering. Reports suggest that improper seal maintenance can lead to leaks, impacting vehicle performance. Seals should be inspected regularly to prevent unwanted fluid loss.

Another critical part is the hydraulic fluid. It enables smooth movement and response. The type of fluid used can affect temperature stability and performance duration. A study indicates that using substandard fluid can shorten the lifespan of the cylinder. Regularly changing the hydraulic fluid is essential for optimal operation. Inadequate maintenance can result in increased risks on the road. Identifying these flaws can improve vehicle safety and reliability.

What is a Steering Cylinder and How Does It Work? - Components of a Steering Cylinder and Their Roles

| Component | Description | Function |

|---|---|---|

| Cylinder Body | The main structure that houses internal components. | Provides support and contains hydraulic fluid. |

| Piston | A movable component within the cylinder. | Converts hydraulic pressure into mechanical force. |

| Seals | Rubber or synthetic materials that prevent leakage. | Ensures hydraulic fluid remains contained within the cylinder. |

| Ports | Entry and exit points for hydraulic fluid. | Facilitates fluid flow into and out of the cylinder. |

| Rod | The elongated piece that moves in and out of the cylinder. | Transfers force from the piston to the steering mechanism. |

Working Principle of a Steering Cylinder Explained

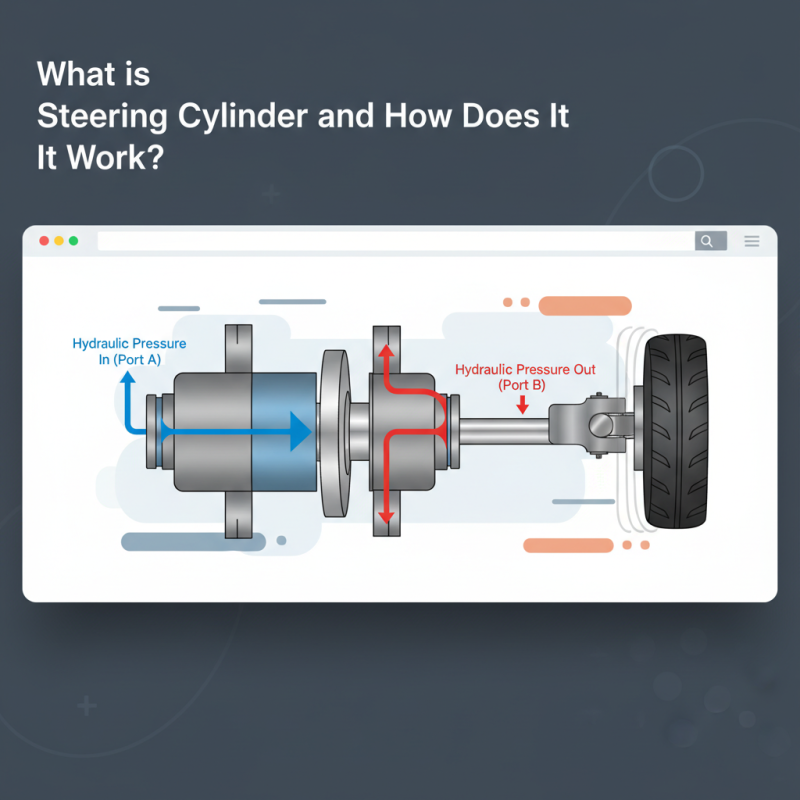

The steering cylinder plays a crucial role in steering systems, particularly in hydraulic mechanisms. It consists of a cylinder where hydraulic fluid is pushed back and forth. This movement translates into the turning of the vehicle’s wheels. The fluid pressure inside the cylinder creates the necessary force to maneuver the steering system.

When the driver turns the steering wheel, it activates the hydraulic pump. This pump sends fluid into the steering cylinder, causing the piston to move. This movement results in the steering linkage turning the wheels. It’s a fascinating interplay of mechanical and fluid dynamics. However, a poorly maintained steering cylinder can lead to leaks or inconsistent steering response.

Understanding the function of the steering cylinder can be complex. Sometimes, the hydraulic system might not respond as expected. Drivers may experience a delayed reaction or stiffness. Regular checks can prevent many issues, but occasional hiccups remind us of the importance of maintenance. Identifying these small yet critical problems can enhance vehicle safety and performance.

Common Types of Steering Cylinders Used in Automotive Applications

Steering cylinders play a crucial role in automotive steering systems. They enable the driver to control the vehicle's direction. Various types of steering cylinders exist, each designed for specific applications.

One common type is the hydraulic steering cylinder. This cylinder uses fluid pressure to assist in steering. It is efficient and provides significant power assistance. However, while hydraulic systems are powerful, they can sometimes be prone to leaks. Regular maintenance is essential to prevent failure.

Another type is the electric steering cylinder, which relies on an electric motor. This system offers precise control and better fuel efficiency. It is lighter than hydraulic systems but may lack the robust feel many drivers expect. Implementing feedback mechanisms remains a challenge and needs improvement.

Both types have their advantages and drawbacks, which can impact vehicle handling and performance. Understanding these nuances is vital for any automotive enthusiast.

Maintenance Tips for Ensuring Optimal Steering Cylinder Performance

The steering cylinder is crucial for vehicle steering. Proper maintenance is key to optimal performance. Regular checks can prevent larger issues. Inspect hoses, connections, and seals for wear. Small leaks can lead to bigger problems.

Fluid levels should be monitored regularly. Low levels can impact performance. Replace the fluid when it gets dirty. Clean filters to avoid blockages. Pay attention to unusual noises. They may signal underlying issues.

Don't overlook routine servicing. It helps identify potential problems early. Neglect can lead to costly repairs later. Take time to review your steering system regularly. Simple actions can extend its lifespan significantly. Always remember, a well-maintained steering cylinder ensures safe driving.