How to Choose the Right Metallurgical Bridge Crane for Your Needs?

When it comes to selecting a Metallurgical Bridge Crane, the choices can be overwhelming. Companies must assess their specific needs carefully. A Metallurgical Bridge Crane is crucial for efficient material handling in various industrial settings.

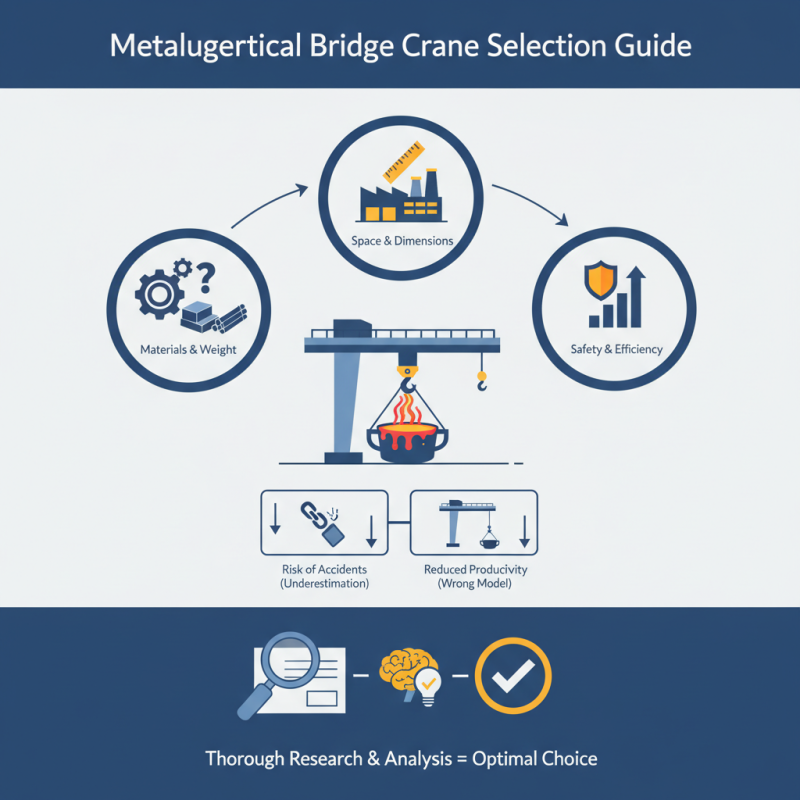

Understanding your operational requirements is essential. What type of materials will be lifted? Consider the weight and dimensions. Also, think about the space available. Not all cranes fit every height or width.

It's easy to overlook details, which may lead to issues down the line. For instance, underestimating load capacities can result in accidents. Choosing the wrong model can impact overall productivity. The right Metallurgical Bridge Crane should enhance efficiency and safety. Therefore, thorough research and analysis are vital before making a decision.

Understanding the Functionality of Metallurgical Bridge Cranes

Metallurgical bridge cranes play a crucial role in steel mills and foundries. Understanding their functionality helps in choosing the right model for your needs. These cranes are designed to lift heavy loads, such as molten metal, with precision. They operate on a fixed track and can span large distances, making them ideal for extensive manufacturing areas.

When selecting a metallurgical bridge crane, consider its lifting capacity and working environment. Humidity and temperature fluctuations can affect performance. Additionally, evaluate the crane’s control system. Is it intuitive? A user-friendly interface can ensure safety and efficiency.

**Tip:** Look for cranes with redundancy features. This ensures safety if one component fails. Also, regular maintenance checks are essential. These can reveal potential issues before they escalate. Engaging with operators about their experiences may lead to valuable insights.

It is vital to reflect on your specific requirements. Are you prioritizing speed or precision? Balancing these factors will help you select the most effective crane for your operations. Remember, the chosen crane will affect your team's productivity and safety.

How to Choose the Right Metallurgical Bridge Crane for Your Needs?

| Crane Type | Load Capacity (Tons) | Span (Meters) | Lift Height (Meters) | Control System | Special Features |

|---|---|---|---|---|---|

| Single Girder Bridge Crane | 5 | 10 | 6 | Remote Control | Lightweight Design |

| Double Girder Bridge Crane | 10 | 20 | 8 | Cabin Control | Heavy Duty |

| Overhead Crane | 15 | 15 | 10 | Wireless Control | High Precision |

| Steel Mill Crane | 50 | 25 | 15 | Control Room | Heat-Resistant |

| Explosive Proof Crane | 20 | 12 | 9 | Remote Control | Safety Features |

Key Specifications to Consider for Metallurgical Bridge Cranes

Choosing a metallurgical bridge crane requires careful consideration of key specifications. First, load capacity is crucial. Most cranes have a range that varies widely. For example, a typical metallurgical crane handles from 5 to 200 tons, depending on the operation's demands. An inadequately rated crane can lead to accidents and costly downtime.

Next, span width is another vital factor. Bridge cranes can range from 10 feet to over 100 feet in span. A proper span accommodates the workspace while maintaining operational efficiency. Too wide an area might necessitate multiple cranes, increasing costs.

Finally, consider the lifting speed. Standard lifting speeds for metallurgical cranes usually fall between 10 to 30 meters per minute. However, higher speeds are often necessary for certain applications, especially in fast-paced industries. When selecting a crane, it’s essential to balance speed with precision. A crane that lifts too quickly may compromise control. It's a critical aspect worth examining closely to prevent inefficiencies.

Assessing Load Capacity Requirements for Your Operations

When selecting a metallurgical bridge crane, load capacity is crucial. It directly affects your operations. What do you need to lift? Heavy metals, large components, or small parts? Each item has a specific weight. Calculating this weight is essential.

Consider the maximum load you may encounter. It's not just about the average. Think about the heaviest loads. Frequently exceeding the rated capacity can lead to failures. These failures can be costly. They may result in downtime or even safety hazards. You don’t want to compromise safety for capacity.

Evaluate your workspace too. The height and width can impact your choice. Consider the crane's lifting height and span. Will it fit into your facility? Tight spaces can pose challenges. Look for solutions to optimize your operation.

Keep in mind, there's no one-size-fits-all solution. You may need to adjust your requirements. Regularly re-evaluate your needs as operations evolve. New materials or processes may require different lifting capacities. Reflect on these aspects to ensure you choose wisely. Making the right choice will enhance your productivity and safety.

Evaluating Safety Features and Compliance Standards

When choosing a metallurgical bridge crane, safety features must be a priority. You need to consider multiple aspects. Look for overload protection systems. They safeguard against lifting beyond capacity. Emergency stop buttons should be easily accessible. This ensures quick response during unexpected situations.

Compliance with established safety standards is crucial. These regulations often vary by region. Make sure the crane meets local codes. Inspect certification documents regularly. This helps maintain compliance and ensures safe operations. Visual inspections are also important. They can reveal wear and tear that may compromise safety.

In your selection process, don't overlook training for operators. Skilled operators can significantly reduce accidents. However, even the best training can’t eliminate all risks. Continual assessment of practices is needed. Regular refresher courses can help. Assigning someone to oversee safety measures is beneficial too. Recognizing flaws in the system is necessary for improvement. Balancing safety with operational efficiency is always a challenge.

Determining Cost-Effectiveness and Maintenance Needs

When selecting a metallurgical bridge crane, cost-effectiveness and maintenance needs are crucial. Evaluating the total cost of ownership is essential. Consider initial purchase price alongside ongoing costs. This includes energy consumption and regular service expenses. A more expensive crane can save you money long-term with energy efficiency.

Tips: Assess your operational demands carefully. Understand the load capacities needed. A crane that is underutilized may seem cost-effective but can be a maintenance burden.

Regular maintenance is indispensable for performance. Poorly maintained equipment leads to breakdowns. This can inflate repair costs and downtime. Establish a maintenance schedule that fits your operational tempo. Frequent inspections can identify issues before they escalate.

Tips: Create a checklist for routine maintenance. Simple tasks often prevent bigger problems. Document any repairs and inspections for future reference. This will help in budgeting and improving operational efficiency.