How to Choose the Right Ball Bearing for Your Project?

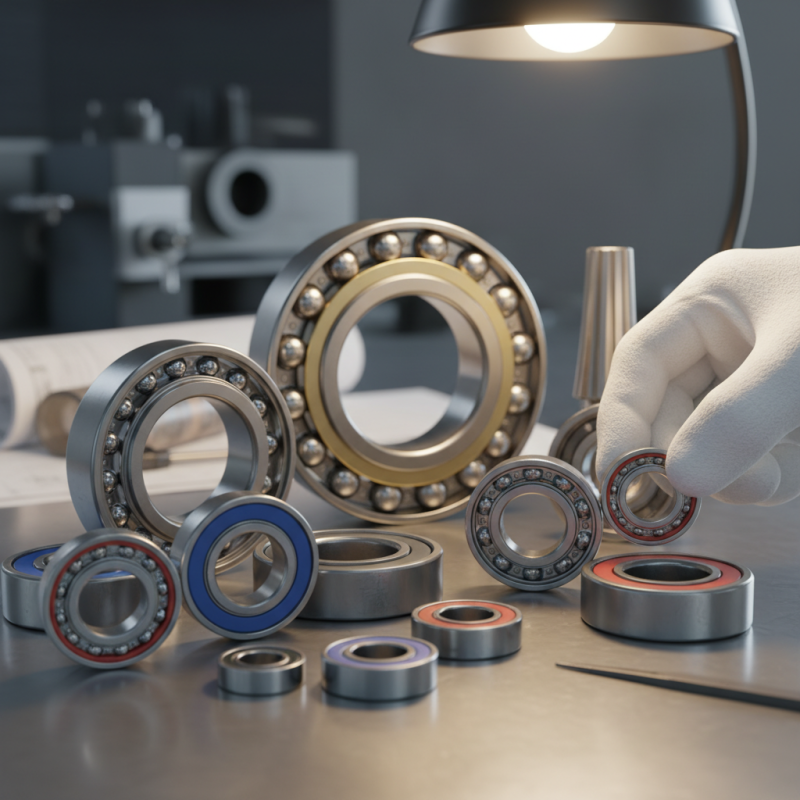

Choosing the right Ball Bearing for your project is crucial. It can significantly affect performance and longevity. Ball bearings are essential in various applications, from small machinery to large manufacturing processes. With many options available, it’s easy to feel overwhelmed.

Different types of ball bearings serve different purposes. Some are designed for high speeds, while others can handle heavy loads. You'll need to assess your project's specific requirements. Consider factors like load capacity, speed ratings, and operating conditions. These elements will guide your choice and ensure you select an appropriate ball bearing.

It’s important to note that even small mistakes can lead to failures. If you choose the wrong type, it may not perform well or fit correctly. This can disrupt operations and lead to unexpected costs. Take time to evaluate your options carefully. The right ball bearing can enhance efficiency, but neglecting to do thorough research can lead to regrets.

Understanding the Basics of Ball Bearings and Their Applications

Ball bearings play a crucial role in various mechanical applications. Understanding these components is essential for anyone working on projects involving movement. They reduce friction between two surfaces, allowing parts to rotate smoothly. Without proper selection, a project may suffer from inefficiency or failure.

Different ball bearings serve different functions. For instance, some are tailored for high speeds, while others excel under heavy loads. Spacing, material, and design all affect performance. You could choose a bearing that looks reliable but may not handle specific conditions well. Sometimes, the simplest solution proves to be the most effective.

In projects where precision is key, overlooking bearing specifications can lead to errors. For example, a bearing meant for lightweight applications might fail under stress. It’s crucial to match the right bearing to your project's requirements. Reflection on past choices can guide future decisions for better outcomes.

Distribution of Ball Bearing Types Used in Various Applications

Key Factors to Consider When Selecting a Ball Bearing

When selecting a ball bearing for your project, consider several key factors. Load rating is critical. Each bearing has a dynamic load rating that indicates its capacity. For instance, a series of studies shows that a bearing with a higher load rating may last up to 50% longer in a high-load environment.

Material also matters. Stainless steel bearings resist corrosion but may not perform well under extreme temperature changes. Ceramic bearings are lighter and may reduce friction but can be prone to cracks under shock loads. Understanding the environment where the bearing will be used is essential.

Tips: Always evaluate where the bearing will be installed. Indoor use allows for different materials compared to outdoor applications. Additionally, lubrication serves as a key element. Proper lubrication can extend bearing life significantly. Neglecting this may lead to unnecessary failures. Check the manufacturer's specifications for proper maintenance intervals.

Lastly, remember that not all projects demand the top-grade bearings. Sometimes, standard options suffice. Rethink your needs to avoid overspending.

How to Choose the Right Ball Bearing for Your Project? - Key Factors to Consider When Selecting a Ball Bearing

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Material | Application |

|---|---|---|---|---|

| Deep Groove Ball Bearing | 100 | 6000 | Steel | Electric Motors |

| Angular Contact Ball Bearing | 150 | 3000 | Ceramic | Machine Tool Spindles |

| Self-Aligning Ball Bearing | 200 | 4000 | Stainless Steel | Pumps |

| Thrust Ball Bearing | 80 | 2000 | Brass | Elevators |

| Miniature Ball Bearing | 30 | 8000 | Plastic | Toys |

Different Types of Ball Bearings and Their Uses

When selecting the right ball bearing for your project, understanding the different types is crucial. There are several common types of ball bearings available, each serving unique purposes. For example, deep groove ball bearings are popular in electric motors due to their versatility. They can handle both radial and axial loads effectively.

Furthermore, angular contact ball bearings are designed for applications that require higher precision. These bearings can handle combined loads, making them suitable for high-speed applications. The data from industry reports indicates that angular contact bearings can reduce friction significantly, leading to improved efficiency in machinery.

On the other hand, self-aligning ball bearings are ideal for misalignment situations. They offer a certain degree of self-adjustment, which can mitigate potential issues in your setup. However, they might not be suitable for high-speed operations. It's crucial to evaluate your project's specific needs.

Evaluating Load Capacities and Speed Ratings for Your Project

When selecting a ball bearing for your project, load capacity and speed rating are crucial. Understanding these factors can help prevent failure or inefficiency. Load capacity indicates how much weight the bearing can handle. This number should match or exceed the loads in your project.

Next, consider the speed rating. This rating shows the maximum speed at which the bearing can operate safely. Exceeding this speed may lead to overheating and premature failure. For example, a bearing rated for high speeds may not perform well under excessive load. It’s essential to find a balance between load capacity and speed.

Sometimes, the choices can feel overwhelming. You might think you need a high-speed bearing for faster performance. However, if it can’t handle your project’s load, you’ll face issues. Testing and reflecting on past experiences can guide you in making better decisions. Balancing these aspects is not easy, but it's vital for project success.

Tips for Sourcing and Testing Ball Bearings Effectively

Choosing the right ball bearing for your project involves understanding both sourcing and testing. When sourcing ball bearings, look for reputable suppliers. Research their history and customer feedback. A reliable source can save you time and frustration in the long run.

Tips for sourcing: Ask for samples before making large orders. Test the quality of these samples. Pay attention to their construction and materials. Check for any signs of wear or defects. Consider their performance under pressure. It’s essential to ensure they match your project needs.

Testing ball bearings should not be overlooked. Run durability tests to evaluate their lifespan. Check for noise and vibration during operation. These factors can indicate potential issues. Don't rush through testing. An oversight could lead to project delays or failures. Being thorough at this stage can make a significant difference in your project’s success.