Why Buy a Ball Screw for Sale and How to Choose the Best?

In the competitive landscape of manufacturing, choosing the right components is crucial. A reliable ball screw for sale can significantly impact machine performance. According to a report by Market Research Future, the global linear motion system market, which includes ball screws, is expected to grow at a CAGR of 6.1% by 2025. This growth highlights the increasing demand for precision and efficiency in manufacturing processes.

Industry expert Dr. John Harris, a renowned leader in motion control solutions, emphasizes, “Selecting the right ball screw can enhance operational reliability and accuracy.” His insight underlines the importance of making informed decisions when purchasing these components. The right ball screw not only improves machine durability but also enhances the overall productivity of manufacturing systems.

However, the process of selecting the best ball screw for sale can be overwhelming due to the myriad of options available. Factors such as load capacity, form factor, and lead accuracy must be considered. Many users overlook these elements, which can lead to suboptimal performance. A thoughtful approach and attention to detail are essential in making the right choice.

Understanding Ball Screws and Their Applications

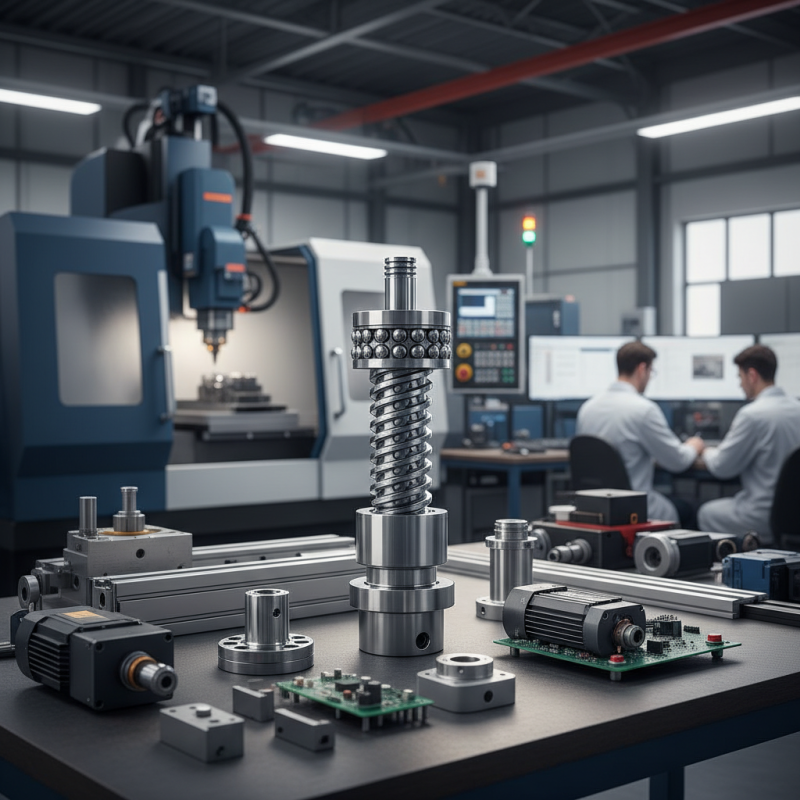

Ball screws are critical components in various industrial applications. They convert rotary motion into linear motion with high efficiency. Their design minimizes friction, allowing for smooth operation. In manufacturing, ball screws are widely used in CNC machines, robotics, and automation systems.

According to industry reports, the global ball screw market is expected to reach approximately $6.3 billion by 2025. Key factors driving this growth include advancements in automation technology and a surge in demand from the aerospace sector. However, selecting the right ball screw can be challenging. Users need to consider load capacity, speed, and environmental conditions. Some ball screws are might not perform optimally under specific circumstances.

Maintenance is another area requiring attention. Regular inspections can prevent inefficiencies. A neglected ball screw can lead to unexpected downtimes. Users often overlook simple lubrication processes, which can drastically affect performance. The choice of a ball screw should focus not just on specifications, but also on the application context.

Advantages of Purchasing Ball Screws for Sale

Purchasing ball screws for sale comes with numerous advantages. They are known for their high efficiency. With a lead screw efficiency of up to 90%, ball screws reduce the input power required for movement. This can lead to significant energy savings in various applications. According to a recent industry report, companies can cut energy costs by over 30% when using high-quality ball screws.

Ball screws excel in precision and repeatability. Manufacturers often achieve tolerances as tight as ±0.01 mm. This accuracy is crucial in automated systems or CNC machines. Many businesses rely on these specifications to enhance their productivity. However, quality varies, so buyers should carefully evaluate sellers. Don’t just trust any offer; look for detailed specifications and certifications.

Tips: When choosing a ball screw, consider its load capacity. This can impact performance under stress. Check for material quality too; using inferior materials can lead to premature failure. Don’t overlook the importance of vendor support. A responsive supplier can be a game-changer in case of issues or questions. Investing time in research pays off significantly in the long run.

Advantages of Purchasing Ball Screws

This chart illustrates the advantages of purchasing ball screws, scoring them on a scale of 10 based on factors such as efficiency, precision, durability, maintenance, and cost-effectiveness. Understanding these benefits helps in making an informed decision when choosing the best ball screw for your needs.

Key Factors to Consider When Choosing a Ball Screw

When choosing a ball screw, several key factors come into play. The load capacity is crucial. Consider the maximum load the screw will handle. Look closely at the specifications. A ball screw should fit your particular application. The material also matters; choose one that offers durability and strength. Steel and aluminum are common options, but different projects may need different materials.

Precision is another factor. Evaluate the accuracy required for your task. Higher precision typically leads to higher costs. It's vital to balance quality and budget. Don't overlook the efficiency of the nut and screw assembly. Higher efficiency translates into better performance, but it can also mean increased maintenance.

Lastly, think about the installation process. Some ball screws are easier to install than others. Complicated assemblies could lead to frustration and extra costs. Reflect on your capabilities and tools available. It’s okay to seek help if you’re unsure about the process. Choosing a ball screw is a critical decision, and taking the time to consider these factors can pay off in the long run.

Comparing Different Types of Ball Screws on the Market

When considering ball screws for your projects, understanding the types available is crucial. Linear ball screws are popular in applications requiring a straight movement. They provide high accuracy and are ideal for CNC machines.

Then, there are miniature ball screws. These are compact and suitable for small devices but may lack load capacity.

Preloaded ball screws offer increased rigidity and improved performance. They have a tighter fit, which reduces backlash. However, they can be more challenging to install and adjust.

Each type has its pros and cons, and the right choice depends on your specific needs. Sometimes, people overlook the installation aspects when selecting ball screws. Failing to consider compatibility may lead to issues later.

Also, think about the environment where the ball screw will be used. Dusty or wet conditions can impact performance. Some may need additional sealing or lubrication.

As a buyer, being informed helps navigate these choices effectively. Take your time to reflect on which type best suits your application. Each choice requires consideration and thoughtfulness to avoid future regrets.

Tips for Ensuring Quality and Performance in Ball Screws

When choosing a ball screw, quality and performance are vital. Look for materials that ensure durability. High-quality ball screws often use hardened steel for greater wear resistance. This type of steel can withstand significant loads and reduce the risk of deformation under pressure.

Examine the precision of the ball screw as well. Check the lead accuracy; it’s crucial for maintaining consistent movement. Consider the ball diameter as it affects the load capacity. Larger diameters can bear more weight but may limit speed.

Visual inspection helps too. Look for any signs of wear or damage on the surface. Imperfections may lead to premature failure. Pay attention to the lubrication system as well. A good design ensures that the ball screw operates smoothly and lasts longer. Don't overlook the importance of proper installation; it influences overall performance significantly.