2026 Best HPMC for Sale Options and Buying Guide

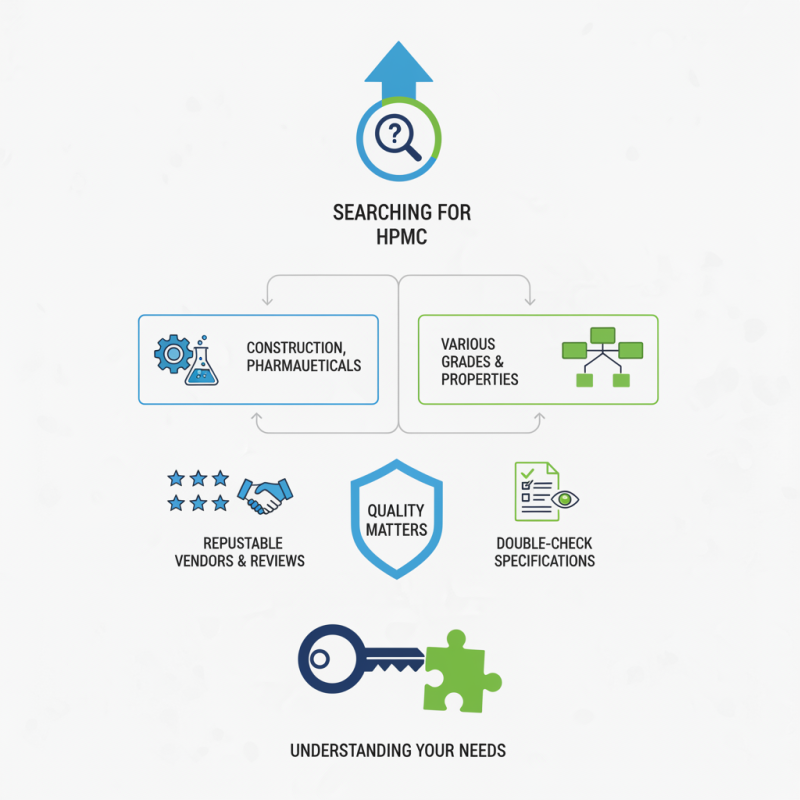

When searching for hpmc for sale, it's crucial to understand what makes a product stand out. HPMC, or Hydroxypropyl Methylcellulose, is widely used in various industries. Its versatility makes it essential for construction, pharmaceuticals, and food applications.

Navigating through different options can be overwhelming. Many brands offer various grades of HPMC, each with unique properties. Some options might not meet your specific needs. Choosing the wrong product can lead to poor performance in your project.

Quality matters, not just price. Look for reputable vendors with reliable customer service. Reading reviews can be helpful. Sometimes, sellers may not provide accurate information about their products. Always double-check specifications before making a purchase. Understanding what you need is key to finding the best hpmc for sale.

2026 HPMC Market Overview: Trends and Demand Analysis

The HPMC market in 2026 shows dynamic shifts in trends. Hydrophilic cellulose ether continues to rise in demand. This increase stems from its versatile use in construction and food industries. As more manufacturers seek alternatives, HPMC becomes a favored choice. Its properties improve product performance, enhancing adhesion and stability.

However, challenges remain. Quality control is a concern, as variations in manufacturing can lead to inconsistent results. Buyers often struggle with pricing transparency. It creates confusion in selecting the right product. Not all HPMC products are created equal, and some might not meet specific needs.

Market demand highlights several key factors. Eco-friendly formulations are increasingly desired. As sustainability trends grow, so does interest in biodegradable options. Users are seeking reliable suppliers. They need assurance of quality and compliance. This includes proper labeling and safety data. Clear communication from suppliers can mitigate confusion. Yet, the market must evolve to meet these demands effectively.

Key Factors Influencing HPMC Quality and Performance

When selecting HPMC, several key factors influence its quality and performance. The viscosity level is crucial. Different applications require specific thicknesses. For instance, a high viscosity may be necessary for thick coatings, while lower viscosity works better in certain adhesives. The purity of HPMC impacts performance too. Impurities can interfere with bonding strength or water retention.

Another important aspect is its particle size distribution. Uniformity in particle size can enhance consistency in performance. Smaller particles tend to dissolve more easily, which is vital for applications like mortars and plasters. The origin of the raw materials is equally significant. Variations in natural sources can lead to differences in final product attributes.

Many users overlook the importance of storage conditions. Improper storage can lead to moisture absorption, affecting viscosity and workability. It's unclear how many users truly consider these factors. Poor choices could compromise product integrity. Reflection on these points can prevent common mistakes. A thoughtful selection process leads to better outcomes in your projects.

Comparison of Top HPMC Brands: Features and Pricing

When considering the best options for HPMC, it's important to evaluate various brands. Different brands offer features that cater to specific needs. Some focus on viscosity control, while others highlight solubility rates. This variety can influence the choice for your project.

Price points also vary significantly among brands. A lower price may suggest basic functionality but could lead to performance issues. Conversely, premium options often feature advanced formulations. However, this doesn’t always guarantee better results. Are you really getting what you pay for?

Evaluating these factors can be challenging. Brand loyalty often clouds judgment. Many users choose familiar names without exploring alternatives. Reflecting on personal experiences could lead to greater satisfaction. Ultimately, selecting the right HPMC should prioritize suitability over brand reputation.

Application Areas of HPMC: Insights from Industry Data

Hydroxypropyl Methylcellulose (HPMC) is a versatile polymer with numerous applications. It is widely used in construction, pharmaceuticals, and food industries. The unique properties of HPMC make it an essential ingredient in various formulations. In construction, HPMC acts as a thickener and stabilizer in mortars and cement, enhancing workability and adhesion.

In the food sector, HPMC serves as a food additive and thickening agent. It helps improve texture and shelf-life. Its use in pharmaceuticals is notable for drug formulation. HPMC is commonly found in tablet coatings, ensuring controlled release and stability. However, sourcing HPMC involves challenges, such as understanding its quality and specifications.

Industry data indicates a growing demand for HPMC, driven by emerging markets. Manufacturers must also consider environmental impacts in production processes. This reflects a need for constant improvement and adaptation. The market is dynamic, presenting both opportunities and obstacles for buyers. As the industry evolves, staying informed is crucial for making effective purchasing decisions.

2026 Best HPMC for Sale Options and Buying Guide - Application Areas of HPMC: Insights from Industry Data

| Application Area | HPMC Type | Viscosity (cP) | Solubility in Water | Typical Use |

|---|---|---|---|---|

| Pharmaceuticals | HPMC K4M | 3000 - 4000 | Cold/Hot | Tablet Binder |

| Construction | HPMC 60SH | 5000 - 6000 | Cold | Thickener for Mortars |

| Food Industry | HPMC E5 | 2000 - 3000 | Cold/Hot | Emulsifier and Stabilizer |

| Cosmetics | HPMC K100 | 1000 - 2000 | Cold/Hot | Thickener for Creams |

| Textiles | HPMC K15 | 1500 - 2500 | Cold | Sizing Agent |

Buying Guide: Choosing the Right HPMC for Your Project

Choosing the right Hydroxypropyl Methylcellulose (HPMC) for your project can be a daunting task. There are various factors to consider. The viscosity, solubility, and thickening properties of HPMC play a vital role in its application. Each project has different requirements. It’s important to identify the specific needs of your project before making a decision.

Tip: Assess the project requirements first. Do you need a high viscosity or better solubility? Testing small samples can save you headaches later.

Another crucial aspect is the application method. Are you using HPMC in a dry mix or liquid form? The preparation process may vary, affecting performance. Look for samples to experiment with. This hands-on approach leads to better choices.

Tip: Keep notes on how different options perform. This reflection can lead to improvements in future projects. Consider the drying time and final texture too, as these will impact your overall success.

In any case, take time to research different options. There may be trial and error. It’s part of the learning process. Stay flexible and open to adjustments as needed. This will help you achieve the best results with your chosen HPMC.