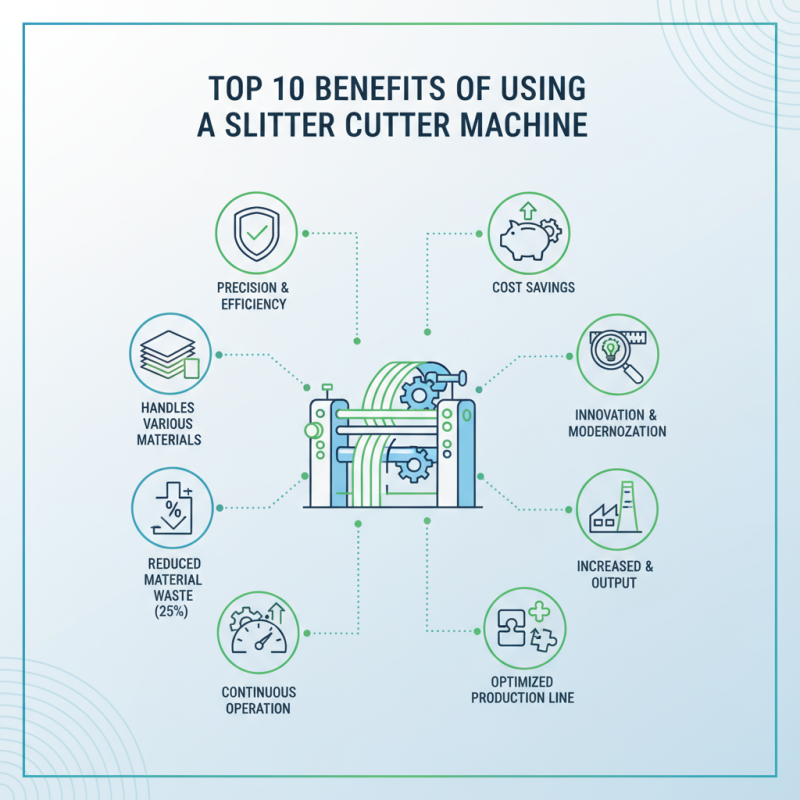

Top 10 Benefits of Using a Slitter Cutter Machine?

The Slitter Cutter Machine has revolutionized cutting processes across various industries. With an increasing demand for precision and efficiency, manufacturers are incorporating advanced machinery. According to a recent market analysis, the slitting machine market is projected to grow by 5% annually. This showcases the rising importance of slitter cutter technology.

One distinct advantage of a Slitter Cutter Machine is its ability to handle various materials. From thin films to thick sheets, this machine excels in versatility. Reports indicate that businesses have reduced material waste by up to 25% when using precision cutting technologies. However, some facilities still rely on outdated methods, leading to increased costs and inefficiencies.

Another key benefit lies in speed and productivity. Slitter Cutter Machines can operate continuously, ensuring high output rates. Some machines can process over 250 meters of material per minute. Yet, not every company has fully embraced this transformation. It’s crucial to recognize these gaps and reflect on potential areas for improvement within production lines.

Advantages of Precision Cutting with Slitter Cutter Machines

Slitter cutter machines provide essential advantages for precision cutting. These machines are widely used in several industries, from packaging to textiles. The accuracy they offer ensures clean cuts without fraying or damage. Each slice is consistent, leading to better end products. This uniformity improves production quality significantly.

When using a slitter cutter, it’s vital to maintain the equipment well. Regularly check the blades for sharpness. Dull blades can lead to uneven cuts. This not only wastes materials but also affects overall efficiency. Clean the machine frequently to avoid contamination.

Another point of consideration is to keep safety as a priority. Ensure operators understand how to use the machine. Proper training can prevent accidents and injuries. Create a checklist for the setup process. Attention to detail here pays off greatly in the production flow. Missed steps can lead to costly errors. Overall, a slitter cutter machine can enhance precision greatly but comes with important responsibilities. Implement these tips for optimal outcomes.

Top 10 Benefits of Using a Slitter Cutter Machine

| Benefit | Description | Impact on Production |

|---|---|---|

| Enhanced Precision | Provides accurate cuts according to specifications ensuring quality control. | Reduces waste and rework. |

| Increased Efficiency | Speeds up the cutting process, allowing more output in less time. | Boosts overall productivity. |

| Versatility | Can handle a wide range of materials, including paper, film, and metals. | Allows for processing multiple product types. |

| Cost-effectiveness | Reduces labor costs and material wastage through efficient cutting. | Improves profit margins. |

| Safety Features | Includes built-in safety measures to protect operators. | Reduces risk of injuries on the production floor. |

| Easy Maintenance | Requires minimal upkeep, saving time and resources. | Keeps production lines running smoothly. |

| Automation Integration | Can be easily integrated into automated production lines. | Enhances workflow and efficiency. |

| Quality Enhancement | Improves the overall quality of final products with precise cuts. | Increases customer satisfaction. |

| Space Saving | Compact designs free up valuable floor space in production layouts. | Allows for better use of factory space. |

| Reduced Turnaround Time | Swift processing times lead to quicker delivery of finished products. | Enhances business competitiveness. |

Enhanced Production Efficiency in Manufacturing Processes

Slitter cutter machines are essential tools in modern manufacturing. They improve production efficiency significantly. According to a recent report by the National Association of Manufacturers, companies using advanced slitting technology saw a 30% increase in operational productivity. This boost stems from faster processing times and reduced material waste.

Precision is crucial for manufacturers. A slitter cutter ensures consistent cuts across various materials, from paper to metal. An industry study stated that manufacturers using these machines achieved a 15% reduction in material costs. This cost savings is critical in competitive markets, where price and efficiency determine success. Yet, it is important to maintain these machines well. Neglect can lead to issues like uneven cuts or increased downtime.

While slitter cutters offer many benefits, challenges exist. Training staff to operate these machines can be daunting for some facilities. Moreover, initial setup costs may deter smaller manufacturers from investing. It’s essential to weigh the benefits against these potential hurdles. Continuous reflection on operational practices can help streamline integration and enhance overall results.

Cost-Effectiveness of Slitter Cutter Machines for Businesses

Slitter cutter machines are a game-changer for many businesses. They improve efficiency in cutting materials like paper, plastic, and textiles. This machinery saves both time and labor costs. When production runs faster, it can lead to higher profit margins. Accurate cuts also minimize waste. Less waste means reduced material costs, which is essential for a business to thrive.

However, initial investments in slitter cutter machines can be daunting for small businesses. Not every company can afford top models right away. Additionally, they require proper training for operators. Mistakes can happen, leading to potential setbacks. Finding a balance between cost and functionality is crucial. Businesses must evaluate their needs realistically, perhaps starting with a basic model. It’s vital to consider long-term savings versus upfront costs. The right choices can lead to increased productivity and reduced operational costs over time.

Versatility in Material Handling and Cutting Applications

The versatility of slitter cutter machines significantly enhances material handling and cutting applications. These machines can process various materials like paper, plastic, and metal. According to industry reports, slitter cutter machines improve productivity by up to 30%. They adapt well to different thicknesses and sizes, making them suitable for diverse industries.

For optimal use, consider the machine's speed settings. Fast speeds can reduce cutting time, but may compromise quality. Ensure that operators are trained to adjust these settings based on the material requirements. It’s crucial to balance speed with accuracy.

Regular maintenance is also vital for versatile applications. Inspection and cleaning help prevent unexpected downtimes. A report by the Manufacturing Industry Institute states that routine maintenance can extend equipment life by 15%. Keep a log of maintenance activities to identify patterns and recurring issues. This practice allows for timely interventions and better operational efficiency.

Top 10 Benefits of Using a Slitter Cutter Machine

Improvement in Product Quality and Consistency Through Accurate Cuts

Using a slitter cutter machine enhances product quality significantly. Precise cuts ensure uniformity in materials. This accuracy reduces waste and enhances the final product's appeal. When every piece is similar, it improves customer satisfaction. Consistency is key in production.

However, achieving precision isn’t always straightforward. Machines require regular maintenance. Misalignment or dull blades can lead to inconsistent cuts. Sometimes, operators may rush, overlooking the setup. Such errors can diminish overall quality. Investing in training and regular checks can mitigate these issues.

Ultimately, the benefits of accurate cuts far outweigh the challenges. Improved quality can lead to higher sales and customer loyalty. Every cut made with precision tells a story of care and expertise. It reflects a brand's commitment to excellence. Balancing speed and accuracy is essential.