2026 Top Laser Cutting Machines What You Need to Know?

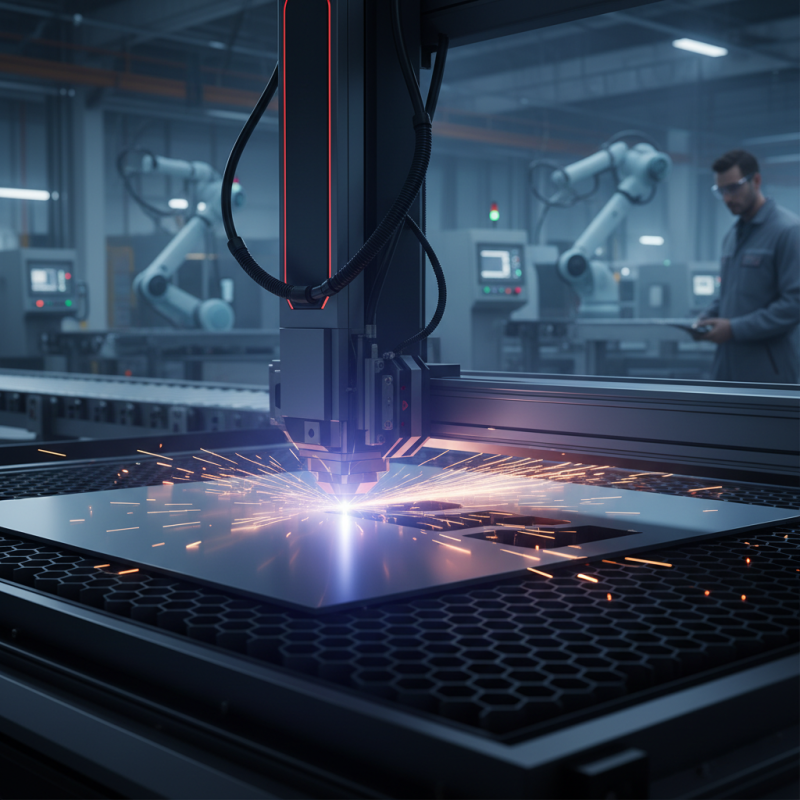

As industries evolve, the demand for precision machining is surging. The laser cutting machine market is poised for significant growth. Research shows a projected increase of over 7% annually until 2026. Companies are increasingly investing in advanced technology for efficiency. Traditional methods often fall short in accuracy and speed when compared to laser systems.

laser cutting machines offer high precision with minimal waste. They can handle diverse materials, from metals to plastics. This versatility draws interest across different sectors. However, not all machines perform equally. Users must assess factors like wattage, speed, and software compatibility. These elements impact the effectiveness of a laser cutting machine.

Despite the clear advantages, challenges remain. Maintenance can be costly, and operator training is essential. Users might encounter issues with machine calibration and setup. Continuous improvement is necessary to stay competitive in this rapidly changing field. Careful research and selection can prevent pitfalls. Understanding the emerging trends will be crucial for making informed decisions.

Key Features to Consider in 2026 Laser Cutting Machines

When exploring laser cutting machines in 2026, several key features stand out. First, the power of the laser plays a crucial role. A higher wattage typically allows for faster cutting and the ability to handle thicker materials. Users often find that balancing power with precision can be challenging. Overly powerful lasers can cause burning or rough edges on delicate materials.

Another important aspect is the software compatibility. Advanced laser cutting machines now come with user-friendly software that supports various designs. Look for tools that allow easy integration with CAD files. However, some users struggle with the complexity of new software updates. Training may be required to maximize efficiency.

Lastly, consider the machine's build quality. Robust construction leads to better durability and less maintenance. Lightweight machines might be easier to move but can compromise stability. Users sometimes overlook the long-term benefits of a strong build, leading to frequent repairs. It's essential to weigh these features carefully to ensure a satisfactory purchase.

Types of Laser Technologies Used in Cutting Machines

The realm of laser cutting machines utilizes various laser technologies, each with unique advantages. CO2 lasers dominate the market, accounting for over 60% of laser cutting applications. They excel in cutting non-metal materials like wood, plastics, and fabrics. Their efficiency and cost-effectiveness make them a popular choice for many businesses.

Fiber lasers, gaining traction, are increasingly used for metal cutting. They deliver high precision and speed, with energy consumption up to 50% lower than CO2 lasers. Reports indicate that the fiber laser market is expected to grow by over 20% annually. This growth is attributed to their ability to cut through thicker metals with less effort and waste.

However, not all options are perfect. The initial investment for high-quality lasers can be significant. Some businesses report difficulties in training staff to effectively use advanced machines. Moreover, maintenance costs can add up, especially for high-powered systems. Organizations must weigh these factors against the operational benefits and potential for increased productivity.

Top Brands and Models for Laser Cutting in 2026

As we approach 2026, the landscape of laser cutting machines is evolving rapidly. The global laser cutting market is projected to grow at a rate of 7.5% annually. This surge reflects the increasing demand for precision in manufacturing. Many industries, such as automotive and aerospace, rely heavily on advanced laser cutting technology.

In terms of top brands and models, several trends are notable. Many machines now offer higher wattage lasers. This feature allows for faster cutting speeds and cleaner edges. A recent industry report highlighted that machines with over 3000 watts are becoming more common. They can cut through thicker materials, like steel or aluminum, effectively. However, users should consider the initial investment and maintenance costs of these high-end models.

Another emerging trend is the integration of software with laser machines. User-friendly interfaces are becoming standard. This improvement helps operators manage complex tasks easily. Yet, some machines still lack adequate user support. Operators often face a steep learning curve. This could lead to inefficiencies in production. Overall, while the future looks promising, both users and manufacturers need constant evaluations to keep pace with advancements.

Applications and Industries Benefiting from Laser Cutting

Laser cutting technology has transformed numerous industries, creating new applications and opportunities. This technology is pivotal in fields such as manufacturing, automotive, and aerospace. It allows for precise cutting of metal, plastic, and wood. This precision minimizes material waste, increasing efficiency in production lines.

Tips: When considering laser cutting for your project, assess the material you plan to use. Different materials require specific settings. Also, ensure proper ventilation in your work area. This helps to dissipate fumes generated during cutting.

Another significant application is in the medical field. Laser cutting is used to create surgical tools and implants. The accuracy helps maintain high standards in medical manufacturing. However, keep in mind that not all healthcare manufacturers have adopted this technology yet. It requires careful evaluation of benefits versus costs.

Tips: Always research the cutting capabilities of machines. Look for options that offer versatility. Also, consider whether your production needs will scale in future, as this will influence your equipment choice.

2026 Top Laser Cutting Machines - Applications and Industries Benefiting from Laser Cutting

| Machine Type | Power (W) | Max Cutting Thickness (mm) | Speed (m/min) | Applications |

|---|---|---|---|---|

| CO2 Laser Cutter | 150 | 20 | 30 | Wood, Acrylic, Leather |

| Fiber Laser Cutter | 300 | 10 | 40 | Metal, Stainless Steel, Aluminum |

| ULTRA-High Power Laser Cutter | 1000 | 25 | 25 | Thick Metal Sheets, Industrial Applications |

| Green Laser Cutter | 200 | 5 | 50 | Glass, Ceramics |

Future Trends in Laser Cutting Technology to Watch

The laser cutting industry is rapidly evolving. As we look toward 2026, several key trends are emerging in laser cutting technology. One significant trend is the integration of artificial intelligence (AI). AI can optimize cutting paths and improve precision, leading to enhanced efficiency. According to a recent report, AI-driven technologies could reduce waste by up to 30%. This not only saves materials but also reduces operational costs.

Another trend is the advancement of fiber laser technology. Fiber lasers offer higher cutting speeds and better performance on various materials. They are becoming increasingly accessible, making them a popular choice for manufacturers. The latest studies indicate that fiber laser machines are expected to capture over 60% of the market share in the next few years.

Tips for selecting a laser cutting machine include evaluating your material types and thicknesses. Understand your production needs to ensure you choose a system that aligns with your specific requirements. Remember, investing in the right technology now can lead to significant savings and efficiency gains in the future. Additionally, keep an eye on emerging innovations; staying updated is crucial for maintaining a competitive edge.

2026 Top Laser Cutting Machines: Future Trends in Laser Cutting Technology

This chart illustrates the expected advancements in laser cutting technology over the next few years, focusing on key metrics such as Cutting Speed (mm/sec), Precision (µm), and Power Consumption (kW) for different laser technologies.